The Carbon

Footprint of Cement

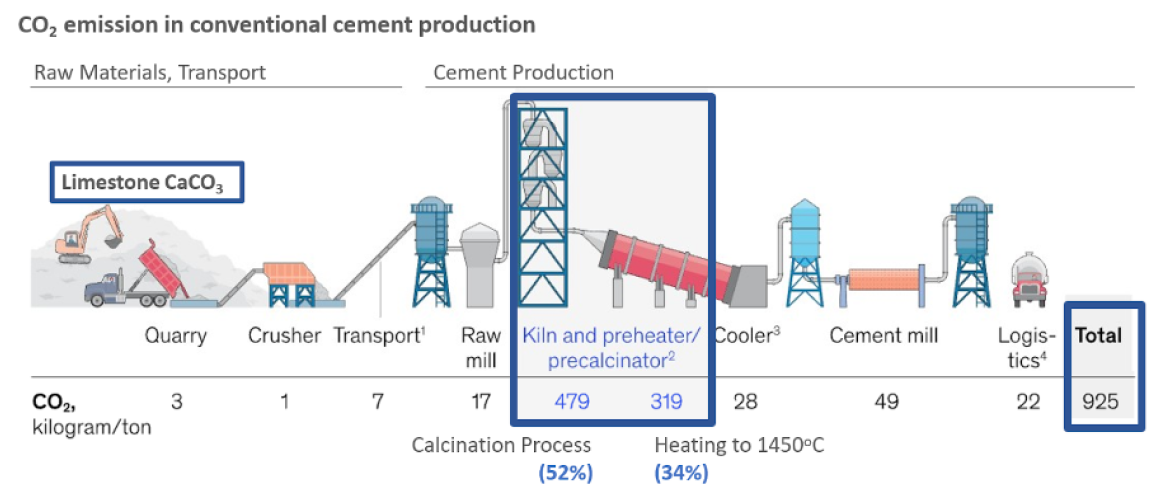

Conventional cement production is responsible for 84% of CO₂ emissions, primarily due to calcination and heating processes.

The Circrete Difference

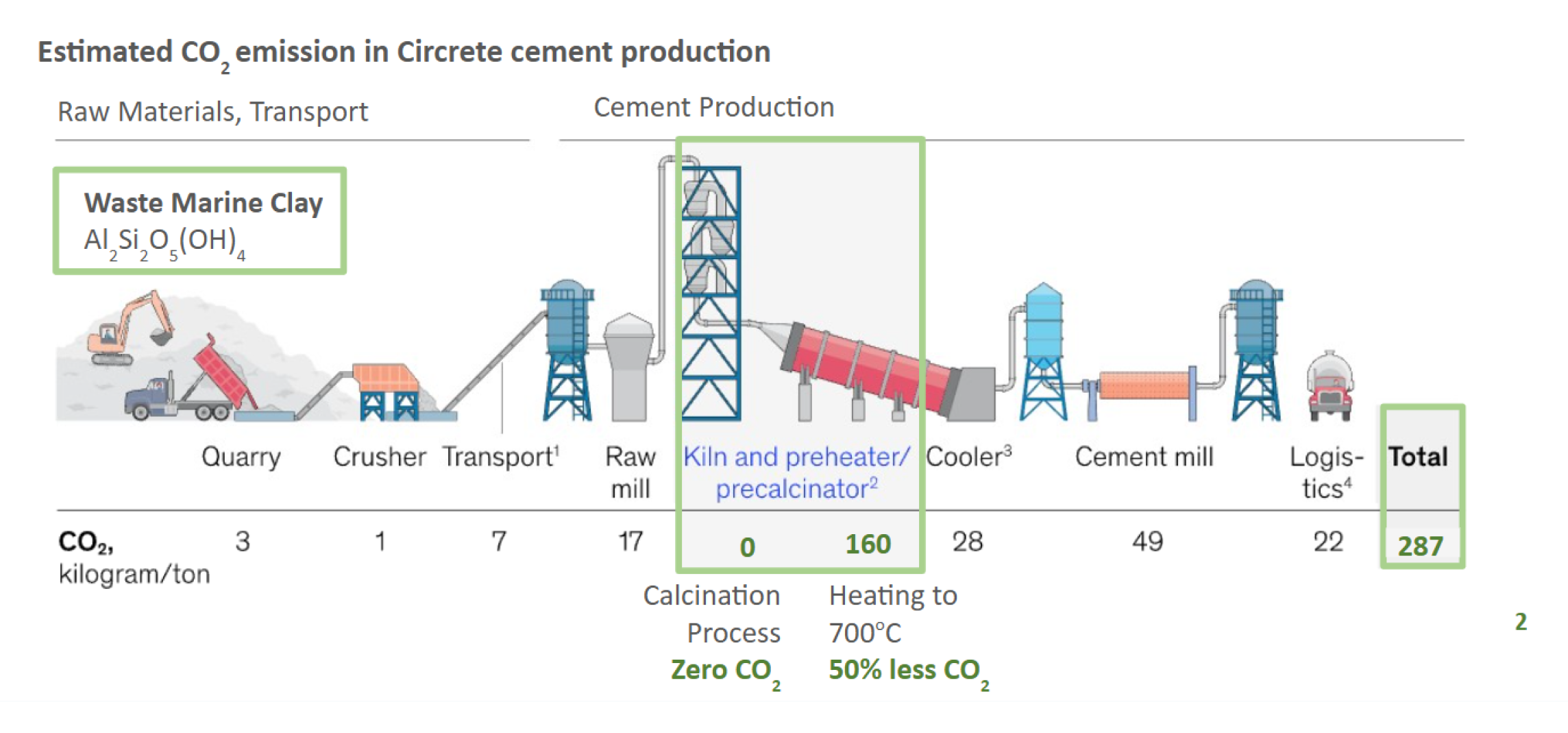

Circrete’s innovative approach transforms the process:

- 0% CO₂ from Calcination

- 50% Less CO₂ in Heating

Circrete reduces CO₂ emissions by up to 70% compared to conventional cement while delivering better performance.

Why Choose Circrete

Circrete Advantages

PRODUCT SPECIFICATION

FEATURES

VALUE

Raw Material Source

Locally sourced waste marine clay (abundant and low-value)

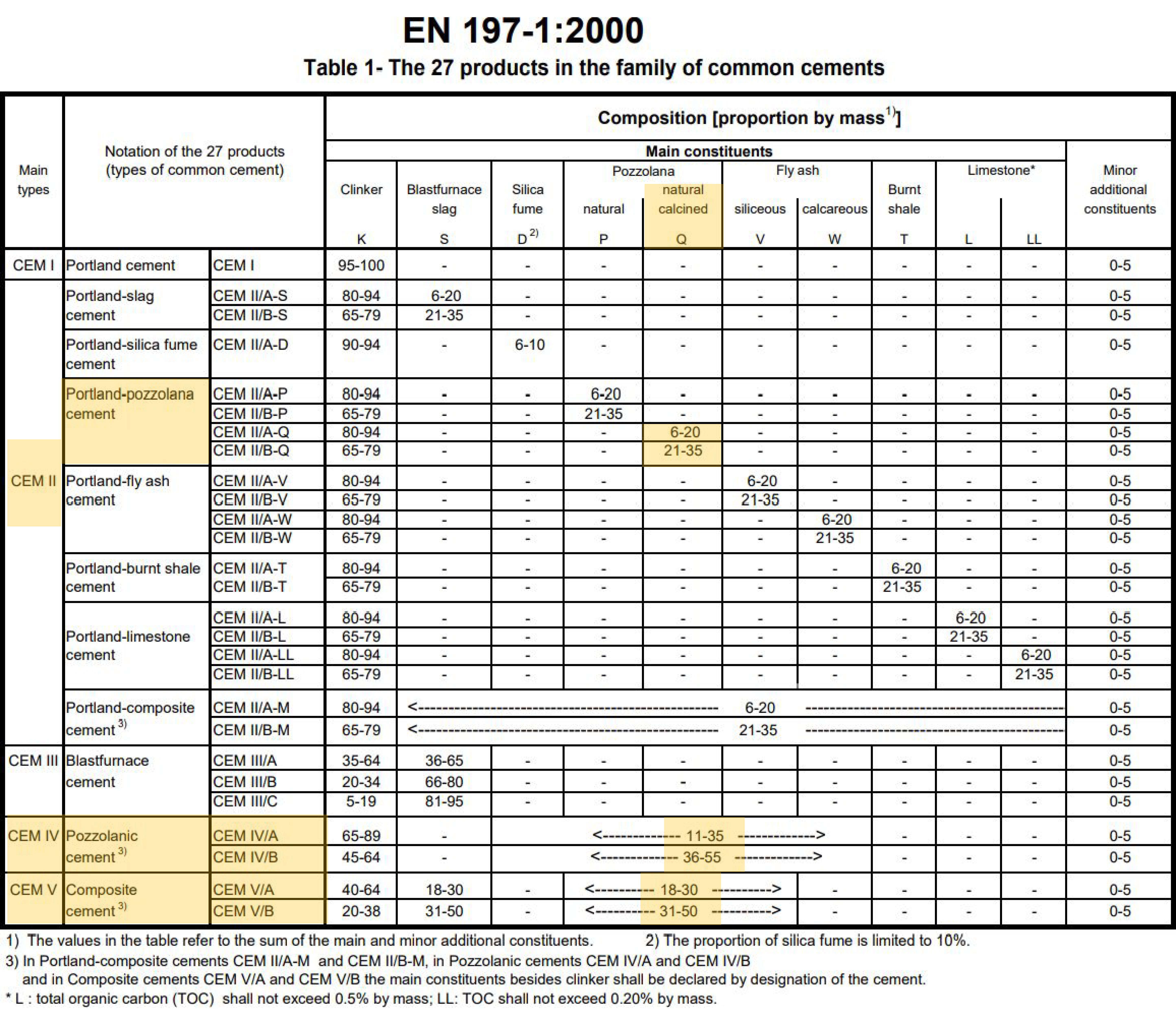

Cement Type (EN 197-1)

CEM III/A-Q (6–20% cement replacement)

CEM III/B-Q (21–35% cement replacement)

Product Compatibility

Compatible with all constituents of concrete mix materials

Carbon Emission in Production

Up to 70% reduction as compared to normal cement

Permissible Concrete Strength

Up to Grade 60

Chloride Ion Penetrability (ASTM C 1202)

28-day: Moderate (vs High for normal concrete)

90-day: Low (vs Moderate/High for normal concrete)

Durability & Service Life

More than 300% improvement

Carbon Reduction in Life-Cycle of Asset

Up to 60% reduction in life-cycle embodied carbon

Certified to EN 197-1:2000 Standards

Circrete meets the stringent EN 197-1:2000 standards, ensuring safety, quality, and reliability in every batch.

Circrete Innovation

Leading the Way with Patented Technology

Our innovative green cement technology is backed by x number of patents, reflecting our dedication to sustainability and driving change in the construction industry.

Contact Us

Interested in working together?

Let's discuss how Circrete can help you achieve your sustainable construction goals